Why Does My Model Train Slow Down? Uncovering the Mystery

Model train enthusiasts sometimes experience slowed trains. This article will discuss the key causes of this issue and offer solutions. Understanding the causes and fixing them will keep your model train running smoothly and regularly.

Key Takeaways:

- A voltage drop, not enough power, or bad track wiring can all make a model train move slowly.

- Cleaning the track and making sure there is a steady power supply can help keep the voltage from dropping and the train running at its best speed.

- For steady train performance, track and locomotive problems must be fixed and maintained on a regular basis.

- Keeping the right train speed can be easier if you have the right train set, layout and feeders in the right places.

- Cleaning, lubricating, and maintaining rolling stock correctly is very important to keep trains running smoothly.

Understanding the Impact of Voltage and Power Supply

One of the most important things to look at when trying to fix a slow model train is the voltage and power supply. If there isn’t enough voltage, trains may move more slowly and perform worse. It is important to check both the power source and the track wiring to make sure the power supply works well.

First, take a look at your power source. Make sure that it can give your model train the right amount of voltage and current. If the power source doesn’t have enough capacity, the voltage can drop, which can slow down the train. Bad connections to the power supply can also make the situation worse. Make sure that all of the links are tight, clean, and free of rust.

The quality of your track wiring is just as important. When track wire is dirty or broken, it can stop the flow of electricity and cause the voltage to drop. Clean the track often and check the wiring for any links that are loose or frayed. Check to see that the track is properly grounded and that there are no things in the way of the electricity flowing.

“A power supply with insufficient capacity can cause voltage drop, resulting in a sluggish train.”

You can keep the voltage from dropping and make sure your model train goes smoothly and at the optimal speed by fixing problems with the power supply and voltage. For consistent performance and a better overall model train experience, you need a power source that you can count on and clean track wiring.

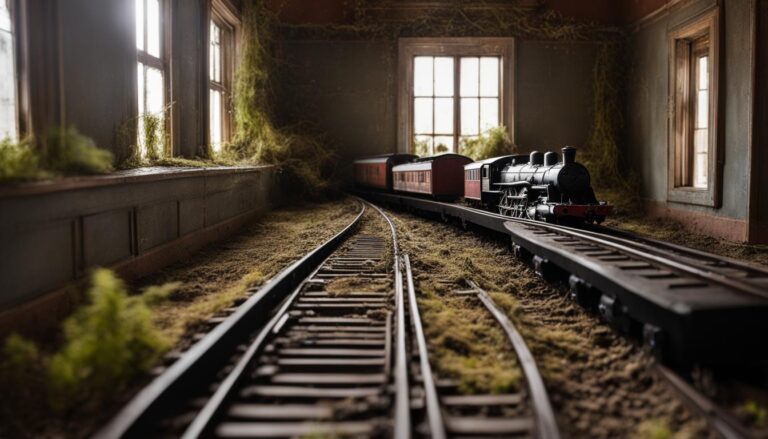

Troubleshooting Track and Locomotive Problems

When model trains move more slowly, issues with the track or the locomotive are often to blame. Over time, rust and other debris can build up on dirty tracks, making them less smooth for your train to move on. Cleaning your tracks on a regular basis is important to keep your train moving at the best speed. A clean track not only reduces friction but also makes the track more electrically conductive, which lets the power flow easily to the locomotive.

You can clean your track well with isopropyl alcohol on a soft cloth, a track cleaning fluid, or a track cleaning car. Make sure to get rid of all the dirt, dust, and oil that you can see. Check the rail joiners that connect the different sections of track as well. Rail joiners that are too loose or not lined up right can stop the flow of electricity and slow down trains. Make sure the rail joiners are tight and straight so that the train can run without any problems.

Track problems and train problems can both slow things down. When an axle is dirty, the wheels can’t turn as well, which slows down the train. For the best results, engines need to be serviced regularly. Remove dirt and other things from the wheels with a soft cloth or cotton swab. A little model train oil on the wheels and gears will make sure they work smoothly. These regular repair checks will keep your model train in good shape and stop problems before they happen.

Common Track and Locomotive Problems

- Dirty track causing friction and hindering train movement

- Loose or misaligned rail joiners disrupting the electrical flow

- Dirty axles impeding the smooth rotation of wheels

“Regularly cleaning the track and ensuring smooth rail joiners can help maintain optimal train speed.”

| Track and Locomotive Troubleshooting Tips | Description |

|---|---|

| Regularly clean the track | Remove dirt, dust, and oil residues to minimize friction and improve electrical conductivity. |

| Inspect and secure rail joiners | Ensure proper alignment and secure attachment of rail joiners to maintain uninterrupted electrical flow. |

| Clean and lubricate the axles | Remove dirt and debris from axles and apply a small amount of model train oil for smooth rotation. |

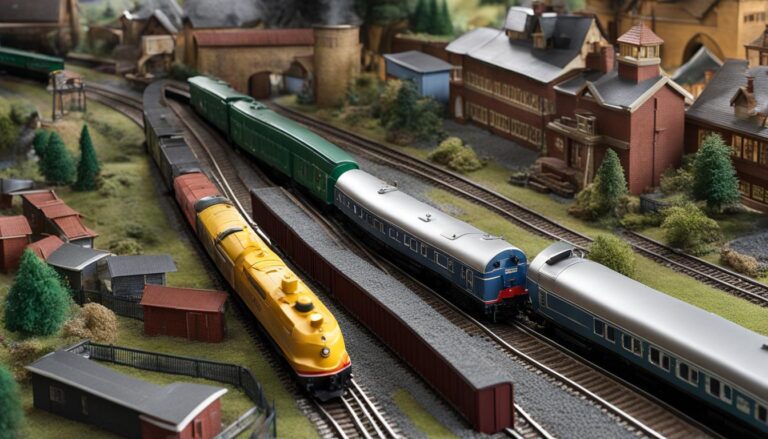

Optimizing Train Set and Layout Configuration

The layout and setup of your train set are very important for getting the fastest speed out of your model train. Your train may move more slowly if there are uneven parts of the track or track sections that don’t have enough power. Also, feeders that are not put correctly can cause power to go out along the track. To keep your trains moving at the best speed, make sure your layout and train set are set up correctly.

Uneven sections of track are a regular problem that can slow down trains. Track sections that aren’t level make the area your train travels on less stable, which can slow it down. It is suggested that you check your track sections often and make any necessary changes to keep the whole surface smooth and level.

Furthermore, a section of track that doesn’t have enough power can make trains move more slowly or even stop. To fix this, you should make sure that your track has the right power. To do this, put feeders at regular intervals along the train to make sure there is always power. This will help keep the train’s speed at the best level and stop power loss.

| Train Set Configuration Tips | Layout Configuration Tips |

|---|---|

| Ensure all track sections are even and level. | Plan and design your layout to allow for smooth train movement. |

| Regularly inspect and adjust track sections as needed. | Position feeders at regular intervals along the track to ensure consistent power supply. |

| Consider using flex track for more flexibility in layout design. | Ensure smooth transitions between track sections to prevent train slowdowns. |

By optimizing your train set and layout configuration, you can help maintain optimal train speed and enhance your overall model train experience.

Considering the Impact of Rolling Stock

What kind of rolling stock you have and how well it’s maintained will affect how fast and well your model train or railroad works. The locomotives and carriages that make up the rolling stock can have a direct effect on how quickly your trains run and whether they slow down. To get the most out of your rolling stock, you need to pay close attention to its care and repair.

Regularly cleaning and lubricating locomotives and carriages keeps them running smoothly. Dirt and other particles can build up on wheels and axles, slowing them and increasing friction. These parts can be cleaned and lubricated regularly to keep trains working smoothly and swiftly.

Choosing the right moving stock for your model railway is just as important as keeping it in good shape. There may be a range of power and performance levels for different engines and carriages. Think about the unique needs of your layout and pick rolling stock that can handle the operations you want to run. This will help make sure that your trains stay at the speed you want them to go and can easily move around the track.

Table: Rolling Stock Maintenance Checklist

| Maintenance Task | Frequency |

|---|---|

| Cleaning locomotive wheels and axles | Every 2-3 months |

| Lubricating locomotive gears and axles | Every 6-12 months |

| Inspecting carriages for loose parts | Every 3-6 months |

| Replacing worn-out or damaged wheels | As needed |

If you do these maintenance jobs on a regular basis, you can keep your rolling stock in great shape and keep your model railway or railroad from slowing down. Make sure that the rolling stock you choose fits the needs of your plan, and check and fix your locomotives and carriages on a regular basis to get the best performance.

Conclusion

In conclusion, fixing a model train that is moving slowly is important to keep it running at its best. You can keep your model train running easily by taking care of common issues like voltage drop, track and locomotive issues, train set and layout configuration, and rolling stock maintenance.

Voltage drop from not enough power or bad track wiring is one of the main things that affects train speed. To keep this from happening, make sure your power source is strong enough and clean your track often so dirt doesn’t build up. Keeping the power source steady and the rail joiners smooth will help the train stay at the right speed.

Also consider rolling stock’s impact on train performance. Keep locomotives and carriages clean and lubricated to avoid friction-related slowdowns. Maintaining your rolling stock is crucial to running your model railway or railroad smoothly.

Consider rolling stock’s effect on train performance. To reduce friction-related slowdowns, clean and lubricate locomotives and carriages. Running your model train or railroad smoothly requires rolling stock maintenance.

By implementing these troubleshooting tips and conducting regular maintenance, including cleaning the track, paying attention to the power supply, and taking care of your rolling stock, you can enhance your model train experience and enjoy consistent, smooth operation.

Frequently Asked Questions

1. Why is my model train slowing down on the track?

If your model train is slowing down, several factors such as voltage drop, dirty track, or axle issues may be the cause. Check for any grime or voltage irregularities that may be hindering the train from running smoothly.

2. How can I troubleshoot my slow model train?

To make your model run smoothly, it’s essential to troubleshoot the issue. Inspect the track sections, rail joiners, and power supply to address any poor model train performance and ensure trains run better.

3. What are common causes for a slow model train?

A Hornby train or any model train may slow down due to issues like dirty track, voltage drop, or inconsistent speed. It’s crucial to address these issues for a consistent speed while running your train.

4. How do I keep my model trains running smoothly on the track?

Regular maintenance such as cleaning the wheels and ensuring enough power is essential to keep your trains running smoothly on model train layouts. Pay attention to the rolling stock and the locomotive to maintain optimal performance.

5. What should I do if my train slows down around the track?

If your train slows around the track, check for power supply issues, rail joiners, joints between track sections

Source Links

- https://www.reddit.com/r/mariokart/comments/ukhllp/revealing_how_mario_kart_8_deluxe_ai_works_for/

- https://www.cnn.com/travel/article/orient-express-mystery-solved/index.html

- https://ktla.com/news/ap-us-news/ap-ntsb-investigators-focus-on-design-problem-with-braking-system-after-chicago-commuter-train-crash/